High quality predictions of your 3D printed parts.

| About | ||

|

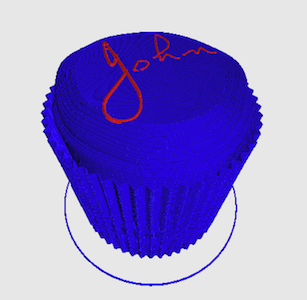

The idea behind Future Additive grew from what seemed to be a simple classroom

assignment back in 2009. The task to design and 3D print a custom cupcake turned

out to be more difficult for the teacher than the students. With only one 3D printer

and each print requiring 12 hours to complete, there wouldn't be enough time for everyone to

finish.

If a physical 3D print wasn't possible, how could they see and learn from their mistakes? What would it take to create a realistic 3D printing previewer? With our backgrounds in material science, physical chemistry, mechanical engineering and software development, we had the right mixture of expertise, but it wasn't a piece of cake. To find the answer we combined high fidelity physics-based models with targeted hardware, software, some ingenuity, and a lot of hard work. Our first simulated print showed us the idea had promise.

The future of additive manufacturing is giving people the tools to see potential mistakes before they happen. And the time and money wasted on failed prints will be a thing of the past. |

||

| A small group of engineers and scientists dedicated to quality 3D printing. | ||